03 FURTILIB

Interneship – 2023

As an intern at MUTECH, a dynamic SAS company specializing in low-temperature solutions for critical industries, I had the opportunity to lead a groundbreaking project in the development of an innovative heating body. This experience allowed me to apply and enhance my skills in various aspects of engineering and project management, particularly in the context of high-stakes technology for the pharmaceutical, hospital, and industrial sectors.

Skills Developed

1. Project Management

- Developed comprehensive project plans and timelines

- Managed tasks from initiation to completion

- Collaborated with cross-functional teams

2. Technical Design and Innovation

- Conceptualized a heating body capable of rapid temperature transitions (300°C to -100°C in 5 seconds)

- Created initial design prototypes

- Explored innovative heating solutions (fabric elements, cords, collars, flexible resistances)

![]()

3. Research and Analysis

- Conducted extensive bibliographic research on materials.

- Analyzed and compared material properties for optimal selection in design.

- Performed preliminary thermal calculations to assess feasibility and efficiency.

4. Economic Analysis

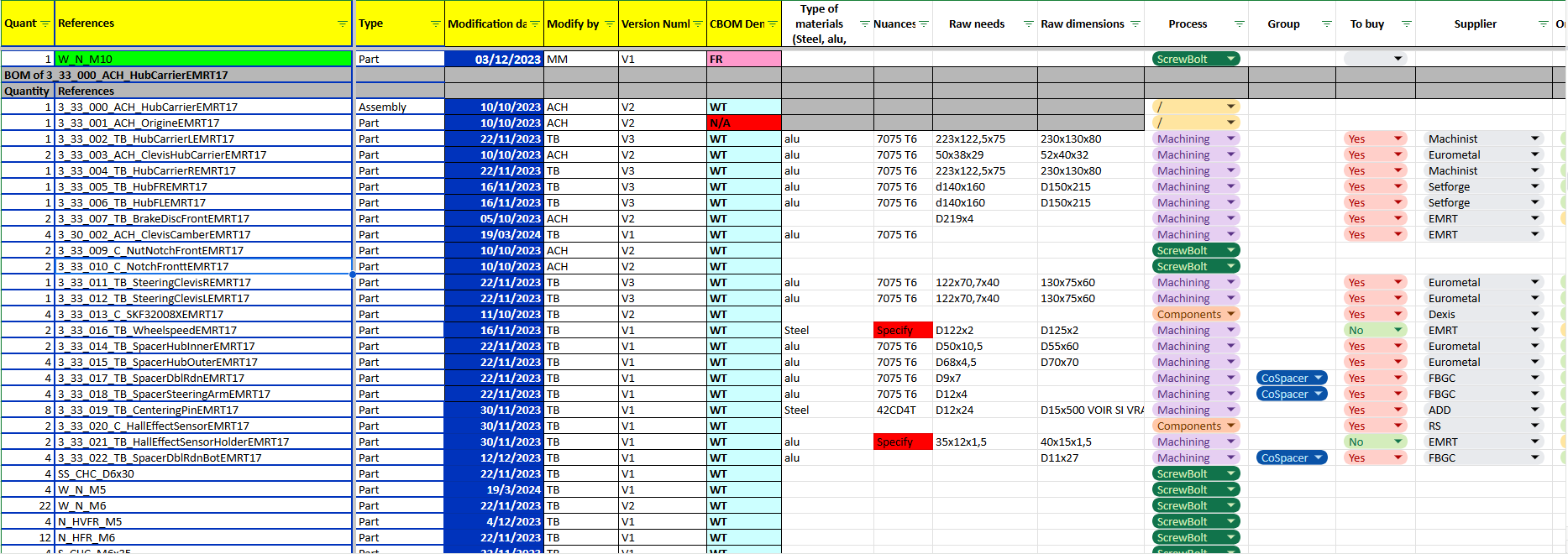

- Prepared detailed bill of materials for components.

- Researched potential suppliers for component costs.

- Conducted profitability analysis based on production volumes and cost considerations.

5. Problem-Solving and Innovation

- Addressed complex engineering challenges in temperature control and its applications.

- Developed solutions for testing electronic components crucial to technology and aeronautics sectors.

This internship provided me with a unique opportunity to contribute to cutting-edge technology development while honing my skills in project management, technical design, and economic analysis. The experience of working on confidential, high-stakes projects has prepared me for future challenges in innovative engineering roles.